Timing Belt Installation Guide

Proper installation of a timing belt ensures longevity, reduces wear, and prevents operational failures. Follow these steps for correct installation and maintenance.

1. Pre-Installation Inspection

Before installation, check the following:

✔ Verify the belt model (correct length, pitch, and width).

✔ Inspect the pulleys for any wear, damage, or misalignment.

✔ Ensure proper pulley alignment to prevent skewing or tracking issues.

✔ Clean the belt and pulleys to remove any dust, grease, or foreign particles.

2. Installation Steps

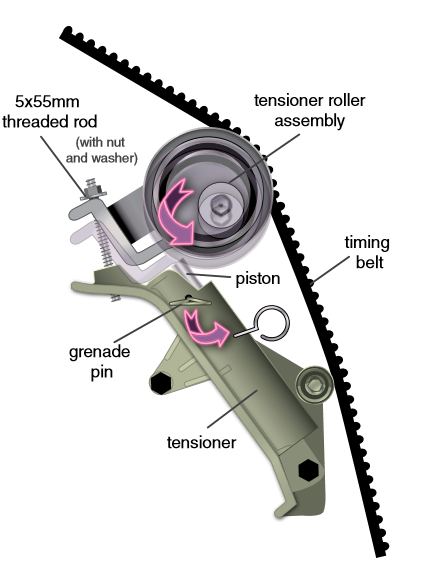

Step 1: Loosen the Tensioning Mechanism

- If a tensioner is present, release it to facilitate belt installation.

- For fixed center distance systems, adjust the shaft spacing if necessary.

Step 2: Position the Belt Properly

- Gently place the timing belt onto the pulleys, ensuring proper engagement with the teeth.

- Avoid bending, twisting, or forcing the belt into position, as this may damage the teeth.

- Ensure correct meshing between the belt and the pulley teeth to prevent misalignment.

Step 3: Adjust the Tension

- Slowly apply the appropriate tension to the belt using the tensioning mechanism.

- Too loose: The belt may slip, reducing transmission accuracy.

- Too tight: Excessive tension increases bearing load and shortens belt life.

- Recommendation: The belt should have moderate elasticity when pressed, and a tension gauge can be used for precise measurement.

Step 4: Check Alignment

- Visually inspect pulley alignment to ensure the belt runs straight.

- Use a ruler or laser alignment tool to check for parallel positioning.

- If misalignment occurs, adjust the pulley position or the tensioner angle accordingly.

Step 5: Test Run

- Manually rotate the pulleys a few times to check for any abnormal noise, jamming, or misalignment.

- Start the equipment at low speed for 5-10 minutes and observe the belt’s movement.

- Once no issues are detected, gradually increase the load to normal operating conditions.

3. Post-Installation Checks & Maintenance

After installation, perform regular inspections:

✔ Monitor belt tension (adjust as necessary after initial run-in period).

✔ Inspect pulleys for uneven wear or loosening.

✔ Check for cracks, missing teeth, or excessive wear on the belt.

✔ Keep the belt clean and free from grease, oil, or chemicals to prevent deterioration.

Conclusion

Loosen tension → Install the belt smoothly → Adjust tension → Align properly → Test run.

Proper tensioning and alignment are crucial for maximizing belt lifespan and efficiency.

Regular maintenance prevents premature failure and ensures long-term stability.

For specific installation requirements based on your machinery, feel free to ask for customized recommendations!

For more installation details, please refer to the Gates belt installation guide.

Loading...

Loading...