Conveyor accessories are essential components that enhance the efficiency, durability, and functionality of conveyor systems. These include rollers, belts, pulleys, idlers, scrapers, belt fasteners, and tracking systems, which ensure smooth material flow, reduce downtime, and improve operational safety. Designed for various industries such as mining, logistics, food processing, and manufacturing, our high-quality conveyor accessories provide reliable performance and long service life.

-

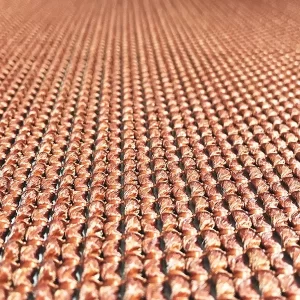

Construction:Flat transmission belt is a common flat rubber belt, also called transmission belt, usually uses high-quality cotton canvas as its skeleton layers.

-

Characteristics:1. The flat rubber belt has the characteristics of high strength, good flexibility and small elongation.

2. Innovative design, adopting advance rubber compound with good adhesion at opposite joint of surface fabric with fillet, delaminating will not occur during operation.

3. Adopting high quality pure cotton canvass, the duck plies have good endurance and will not easily deform.

-

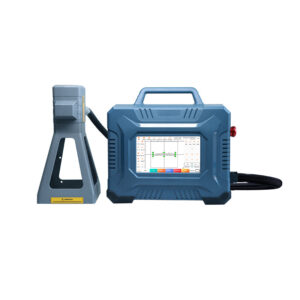

$2,800.00原价为:$2,800.00。$2,500.00当前价格为:$2,500.00。Ideal for branding, product identification, traceability, and compliance

🔹 Permanent, precise, and cost-effective marking solution

🔹 Compatible with multiple materials, ensuring durability and efficiencyIf you need recommendations for laser marking machine models or technical guidance, feel free to ask!

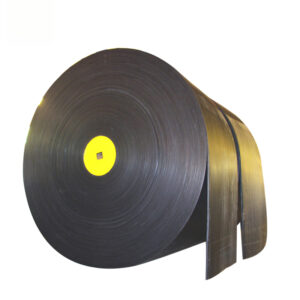

The Textile Conveyor Belt is engineered for high durability and efficiency in industrial applications such as mining, metallurgy, construction, and material handling. It consists of three specialized types:

- Multi-Ply Fabric Conveyor Belt – Designed for strength and flexibility, ensuring stable material transportation across various industries.

- Kevlar Conveyor Belt (DPP) – Provides exceptional heat and impact resistance, making it ideal for high-temperature and heavy-duty applications.

- Crows Foot Weave (CFW) Belt – Built with a unique EP (polyester-nylon) carcass, this belt offers superior rip and tear resistance, five times the strength of conventional belts, and low elongation, making it perfect for demanding environments.

Power transmission belts are widely used to transfer motion and torque in various industries, ensuring efficient mechanical operation. Key applications include:

- Industrial Machinery – Drives motors, pumps, and compressors.

- Automotive Industry – Used in engines, alternators, and air conditioning systems.

- Agricultural Equipment – Powers tractors, harvesters, and irrigation systems.

- Textile & Printing Machines – Ensures precise movement in fabric production and printing presses.

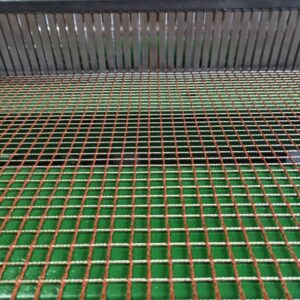

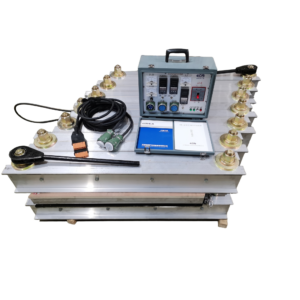

Rubber vulcanizing machine is used to splice conveyor belts by applying heat and pressure, creating a strong, seamless, and durable joint. This process enhances the belt’s tensile strength, wear resistance, and flexibility, ensuring smooth and efficient operation. Vulcanized splicing significantly extends the belt’s lifespan, reduces maintenance, and minimizes downtime, making it ideal for mining, manufacturing, logistics, and heavy-duty industries.

Roller plays a very important role in a belt conveyor system. They consist in the entire transport process to support conveyor belt and move the materials loaded on conveyor belt.

-

Materials:Steel, HDPE, UHMWPE, Nylon, Rubber Coated, etc.

-

Type:Carrying Roller: Troughing roller, Impact roller, Flat carrier roller, Self-aligning carrier roller

Return Roller: Flat return roller, Self-aligning return roller, Rubber disc return roller, Spiral return roller, V-return roller

-

Browse Categories

- All Products

- Rubber Conveyor Belt

- PVC/PU Conveyor belt

- Roller / Idler / Pully

- Conveyor AccessoriesSpillage? Tracking Issues? No matter the problem, we have a solution. CRB provides a variety of conveyor accessories that have been proven to enhance safety, extend asset life, and improve performance…

- Conveyor Belt Fabric