Conveyor belts can suffer from various forms of damage, including severe top cover wear, edge fraying, and tearing. Among these, tearing is one of the most hazardous types of damage, as it can significantly impact belt integrity and operational efficiency. Tearing typically occurs when sharp foreign objects within the conveyed material penetrate the belt or when steel cords become dislodged, leading to longitudinal ripping.

Although conveyor belt tearing is an occasional failure, it can cause catastrophic damage if not promptly addressed. In extreme cases, an entire belt may suffer longitudinal tearing, sometimes stretching thousands of meters, particularly in port operations, resulting in significant economic losses for users.

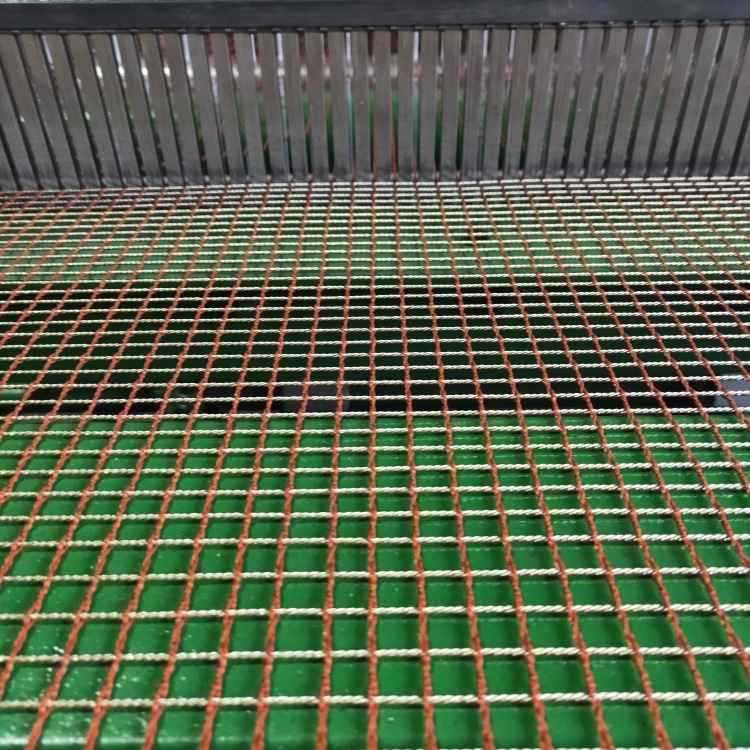

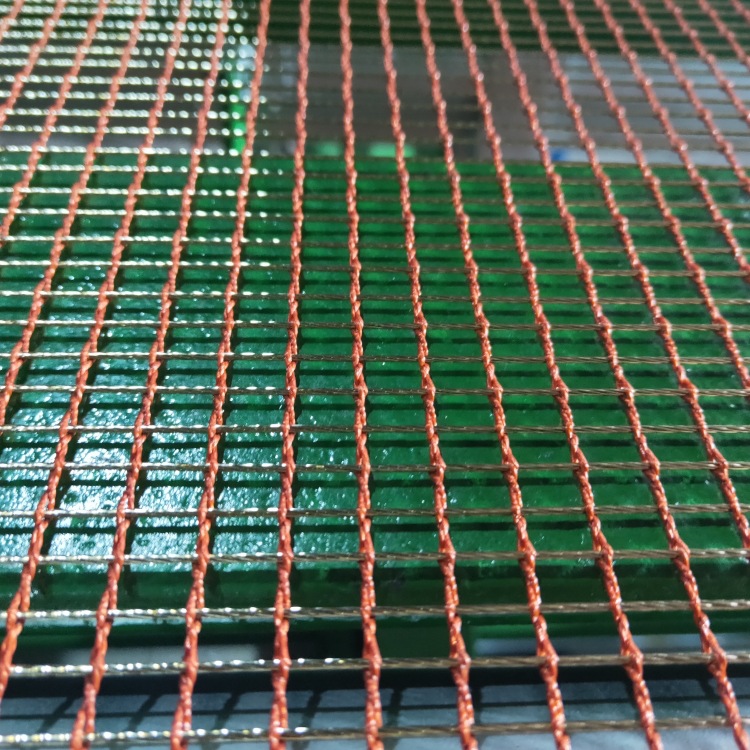

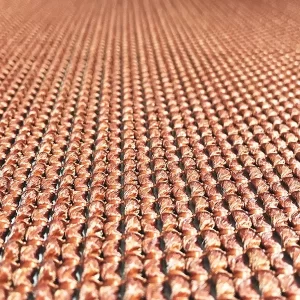

To address these challenges, our company manufactures steel cord anti-tear mesh reinforcement, specifically designed to enhance conveyor belt durability. This anti-tear mesh is composed of copper-plated steel cords, galvanized steel ropes, or rubber-dipped polyester composite ropes, woven into an integrated fabric structure using a specialized braiding process.

This reinforced anti-tear mesh offers the following key advantages:

✔ High structural integrity – Ensures superior durability and resistance to tearing.

✔ Exceptional transverse strength – Enhances conveyor belt resistance to lateral forces.

✔ Uniform and stable interweaving – Maintains consistent spacing for enhanced stability.

✔ Easy handling & installation – Simplifies integration into conveyor belts.

Applications:

The anti-tear mesh reinforcement is widely used in various types of conveyor belts, significantly improving their transverse strength, impact resistance, and tear resistance, ensuring extended belt life and enhanced reliability in demanding industrial environments.

| Specification | Average Weft Tensile Strength/ (N/mm) ≥ | Warp Cord Spacing/mm | Weft Steel Cord Structure | Weft Steel Cord Spacing/mm | Weft Steel Cord Diameter/mm |

|---|---|---|---|---|---|

| BN 35 HE | 35 | 12.0±2.0 | 3×4×0.22 NT HE | 25.0±2.0 | 1.14±0.07 |

| BN 40 HE | 40 | 15.0±2.0 | 3×4×0.22 NT HE | 25.0±2.0 | 1.14±0.07 |

| BN 45 HE | 45 | 12.0±2.0 | 3×4×0.22 NT HE | 20.0±2.0 | 1.14±0.07 |

| BN 50 HE | 50 | 15.0±2.0 | 3×4×0.22 NT HE | 18.0±2.0 | 1.14±0.07 |

| BN 51 HE | 50 | 12.0±2.0 | 3×7×0.20 NT HE | 25.0±2.0 | 1.34±0.08 |

| BN 60 HE | 60 | 15.0±2.0 | 3×4×0.22 NT HE | 15.0±2.0 | 1.14±0.07 |

| BN 61 HE | 60 | 12.0±2.0 | 3×4×0.22 NT HE | 15.0±2.0 | 1.14±0.07 |

| BN 62 HE | 60 | 12.0±2.0 | 3×7×0.20 NT HE | 20.0±2.0 | 1.34±0.08 |

| BN 65 HE | 65 | 15.0±2.0 | 3×7×0.22 NT HE | 18.0±2.0 | 1.52±0.08 |

| BN 70 HE | 70 | 15.0±2.0 | 3×4×0.22 NT HE | 13.0±2.0 | 1.14±0.07 |

| BN 80 HE | 80 | 12.0±2.0 | 3×7×0.22 NT HE | 20.0±2.0 | 1.52±0.08 |

| BN 85 HE | 85 | 12.0±2.0 | 3×7×0.22 NT HE | 15.0±2.0 | 1.34±0.08 |

| BN 90 HE | 90 | 15.0±2.0 | 3×4×0.22 NT HE | 10.0±2.0 | 1.14±0.07 |

| BN 91 HE | 90 | 12.0±2.0 | 3×4×0.22 NT HE | 10.0±2.0 | 1.14±0.07 |

| BN 100 HE | 100 | 15.0±2.0 | 3×7×0.20 NT HE | 13.0±2.0 | 1.34±0.08 |

| BN 110 HE | 110 | 15.0±2.0 | 3×7×0.22 NT HE | 8.5±1.0 | 1.14±0.07 |

| BN 111 HE | 110 | 12.0±2.0 | 3×7×0.20 NT HE | 15.0±2.0 | 1.52±0.08 |

| BN 115 HE | 115 | 12.0±2.0 | 3×4×0.22 NT HE | 8.0±1.0 | 1.14±0.07 |

| BN 125 HE | 125 | 15.0±2.0 | 4×4×0.20 NT HE | 8.2±1.0 | 1.23±0.062 |

| BN 126 HE | 125 | 10.0±2.0 | 4×4×0.22 NT HE | 8.0±1.0 | 1.32±0.08 |

| BN 127 HE | 125 | 12.0±2.0 | 3×7×0.20 NT HE | 10.0±2.0 | 1.34±0.08 |

| BN 150 HE | 150 | 15.0±2.0 | 4×4×0.20 NT HE | 6.8±1.0 | 1.23±0.062 |

| BN 155 HE | 155 | 15.0±2.0 | 3×7×0.20 NT HE | 8.0±1.0 | 1.34±0.08 |

| BN 165 HE | 165 | 12.0±2.0 | 3×7×0.22 NT HE | 10.0±2.0 | 1.52±0.08 |

| BN 200 HE | 200 | 15.0±2.0 | 3×7×0.22 NT HE | 6.4±1.0 | 1.34±0.08 |

| BN 205 HE | 205 | 12.0±2.0 | 3×7×0.22 NT HE | 8.0±1.0 | 1.52±0.08 |

| BN 235 HE | 235 | 12.0±2.0 | 3×4×0.22 NT HE | 4.0±1.0 | 1.14±0.07 |

| BN 250 HE | 250 | 15.0±2.0 | 3×7×0.22 NT HE | 5.1±1.0 | 1.34±0.08 |

| BN 251 HE | 250 | 10.0±2.0 | 3×7×0.22 NT HE | 6.4±1.0 | 1.52±0.08 |

| BN 300 HE | 300 | 15.0±2.0 | 3×7×0.22 NT HE | 5.1±1.0 | 1.52±0.08 |

| BN 315 HE | 315 | 10.0±2.0 | 3×7×0.22 NT HE | 5.1±1.0 | 1.52±0.08 |

| BN 316 HE | 315 | 15.0±2.0 | 3×7×0.22 NT HE | 4.0±1.0 | 1.34±0.08 |

| BN 400 HE | 400 | 15.0±2.0 | 3×7×0.22 NT HE | 4.2±1.0 | 1.52±0.08 |

| BN 410 HE | 410 | 12.0±2.0 | 3×7×0.22 NT HE | 4.0±1.0 | 1.52±0.08 |

| BN 500 HE | 500 | 15.0±2.0 | 4×7×0.25 NT HE | 5.6±1.0 | 2.02±0.12 |

| BN 501 HE | 500 | 10.0±2.0 | 4×7×0.30 NT HE | 7.1±1.0 | 2.40±0.12 |

| BN 630 HE | 630 | 15.0±2.0 | 4×7×0.30 NT HE | 5.6±1.0 | 2.02±0.12 |

| BN 650 HE | 650 | 15.0±2.0 | 4×7×0.25 NT HE | 4.4±1.0 | 2.02±0.12 |

| BN 800 HE | 800 | 15.0±2.0 | 4×7×0.25 NT HE | 3.6±1.0 | 2.02±0.12 |

| BN 801 HE | 800 | 10.0±2.0 | 4×7×0.30 NT HE | 4.5±1.0 | 2.40±0.12 |