Steel Cord is engineered with a single plane of carefully constructed, pre-tensioned steel cords, capable of conveying the toughest loads over the longest distances and at the

highest tensions.

Steel Cord belting is manufactured at our plant in Kwinana, Western Australia. The facility houses three of the world’s largest steel cord press lines, with the capability to produce Steel Cord up to 3200mm wide and 50mm thick.

Reasons to choose Steel Cord belting

Tension capabilities

Highly efficient, precision-engineered steel cords with belt operating ratings up to ST10,000.

Product Quality

Superior results come from the finest materials, meticulous testing, and the best quality control.

Unique design

Thanks to individually pre-tensioned cords with alternating twists, we position cables uniformly in-plane for optimum belt tracking.

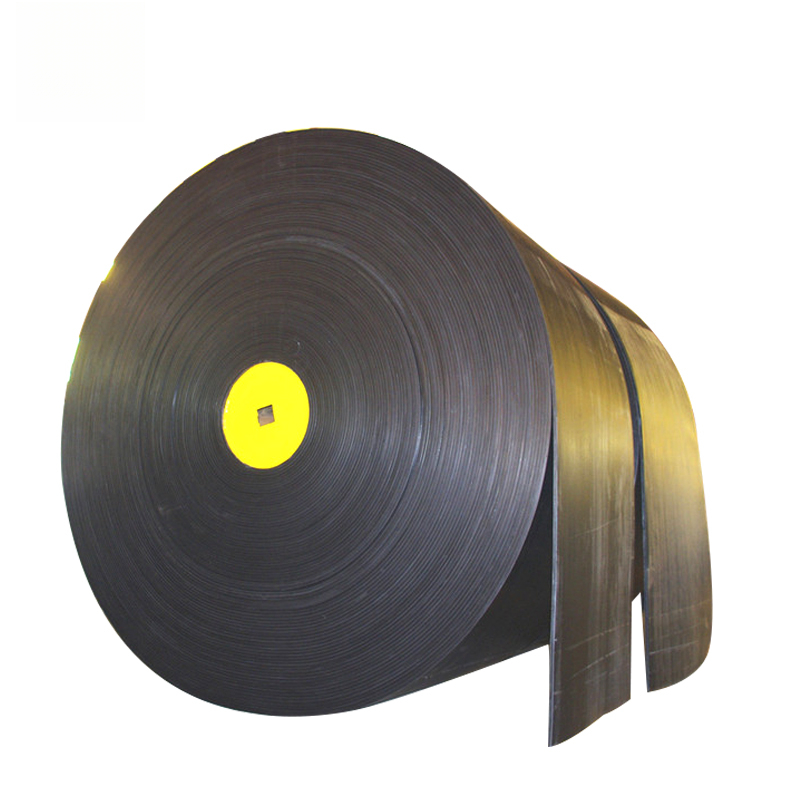

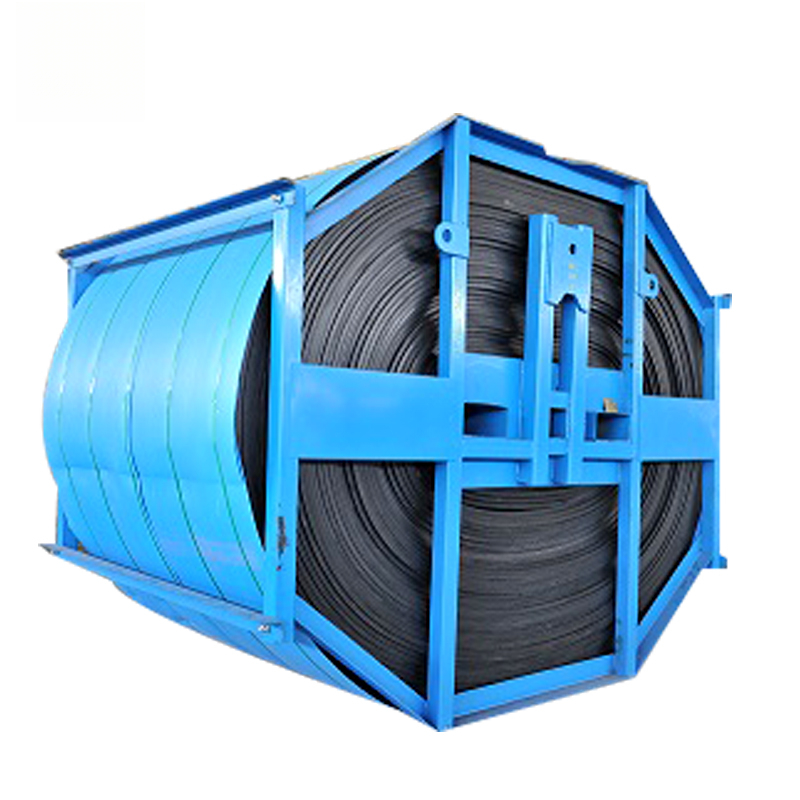

Custom made

Our steel cord beling can be manufactured up to 3200mm wide and up to 70 tonnes roll weight – the heaviest you’ll find in Australia!

Adhesion & corrosion protection

Cable corrosion protection is assured with zinc plated steel cords and high-pressure curing.

Minimal elongation

Belt elongation less than 0.25% of conveyor centres.

Unsurpassed performance

The finest materials, design, manufacturing, and quality control make a problem-free, premium belt.

-

Range:Max strength ST10000, Max belt width 3200mm, Max roll weigth 80ton

-

Standard:GB/T9770,DIN22131,EN ISO 15236,SANS1366,AS1333

-

Applications:Used in coal, ore, port, metallurgical, power and chemical industries, suitable for long distance and heavy load transportation of materials.

-

Special Grade:Heat resistant, FRAS,FRAS & Cold resistant, Abrasion &Acid resistant,LRR

-

Breakers reinforced:NN breaker; Metal breaker; Kevlar breaker

-

Sensor loops:suitable for Becker, Coal Control, Goodyear, be added in belt bottom cover

-

Splice kits:General splice kits,preformed splice kits

Loading...

Loading...