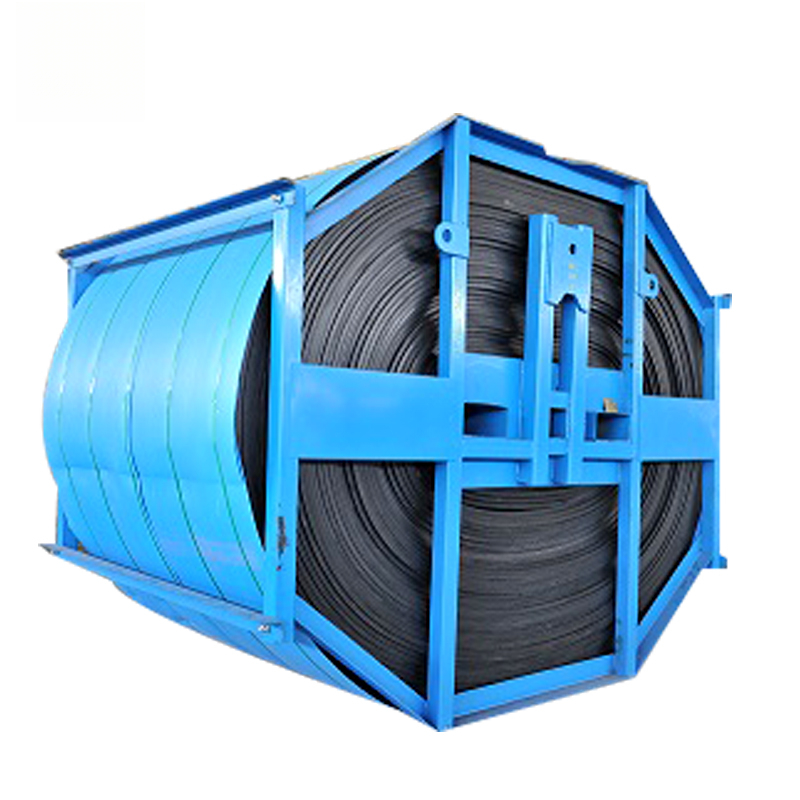

The Textile Conveyor Belt is engineered for high durability and efficiency in industrial applications such as mining, metallurgy, construction, and material handling. It consists of three specialized types:

- Multi-Ply Fabric Conveyor Belt – Designed for strength and flexibility, ensuring stable material transportation across various industries.

- Kevlar Conveyor Belt (DPP) – Provides exceptional heat and impact resistance, making it ideal for high-temperature and heavy-duty applications.

- Crows Foot Weave (CFW) Belt – Built with a unique EP (polyester-nylon) carcass, this belt offers superior rip and tear resistance, five times the strength of conventional belts, and low elongation, making it perfect for demanding environments.

Key Features:

- High tensile strength for heavy loads

- Excellent resistance to wear, impact, and tearing

- Low elongation for stable operation

- High adhesion between layers for durability

- Available in various cover grades to suit different applications

This conveyor belt range ensures efficient, reliable, and long-lasting performance in tough industrial conditions.

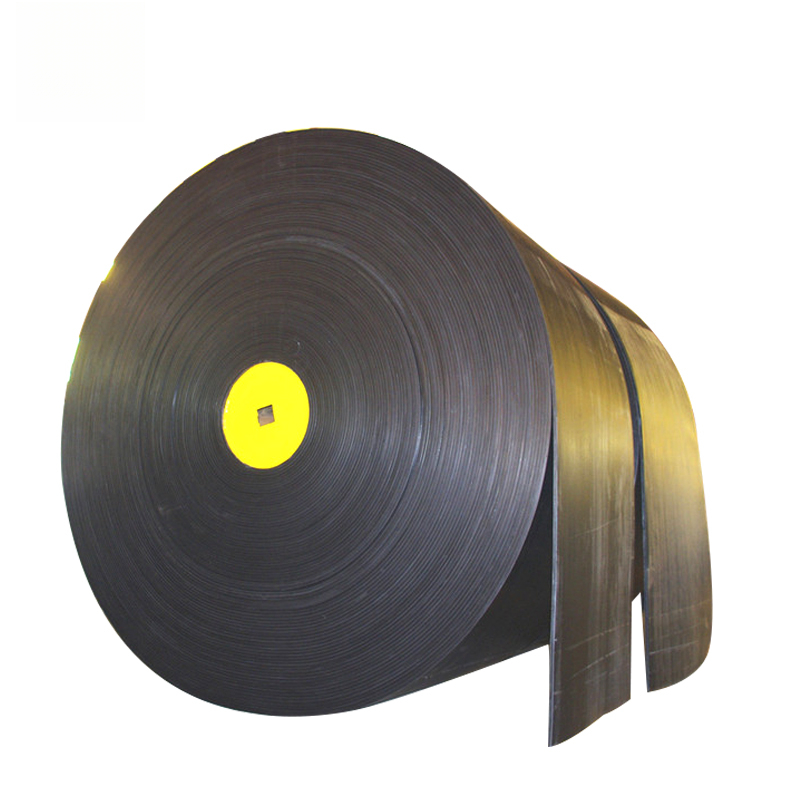

EP conveyor belts are engineered for exceptional tensile strength, superior flexibility, and outstanding resistance to impact and abrasion. These qualities make them an ideal solution for the efficient and reliable transportation of various materials, including bulk goods, aggregates, minerals, and more.

Product Range:

- Maximum Strength: EP3780/6 (EP630)

- Maximum Belt Width: 6500mm

Compliance Standards:

- International Standards: DIN 22102, RMA, SABS 1173, AS 1332, JIS K 6322, and others

Applications:

- Designed for versatile material handling, efficiently conveying bulk materials, aggregates, minerals, and various industrial substances.

Special Grades Available:

- Heat Resistant

- Oil Resistant

- FRAS (Fire Retardant & Anti-Static)

- FRAS & Cold Resistant

- Abrasion & Acid Resistant

- Low Rolling Resistance (LRR)

Reinforced Breakers:

- NN Breaker

- Metal Breaker

- Kevlar Breaker

Sensor Loop Compatibility:

- Suitable for Becker, Coal Control, Goodyear systems and can be integrated into the belt bottom cover.

Splicing Solutions:

- Premium Splice Kits for hot and cold vulcanization, ensuring seamless belt performance and extended operational lifespan.

Loading...

Loading...

Applications:

- Ideal for use in coal mines, mining fields, steel plants, cement production, ports, quarries, power stations, and the chemical industry.

Available Grades:

- General Purpose

- Heat Resistant

- Oil Resistant

- Custom Grades Available Upon Request

Loading...

Loading...

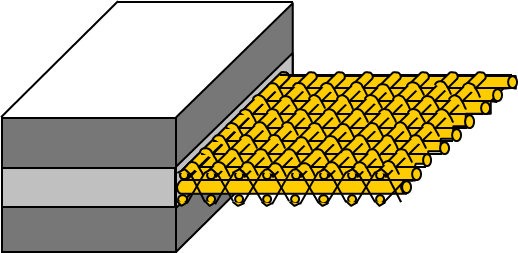

The Crows Foot Weave (CFW) Rubber Conveyor Belt is engineered for exceptional durability and superior resistance to ripping and tearing, offering five times the strength of conventional conveyor belts. Designed for high-stress and demanding applications, it features a unique EP (polyester-nylon) carcass with an advanced weaving structure, including:

- 50% more warp threads (ends) for enhanced tensile strength

- 40% heavier weft yarn for increased durability

- 20% more weft threads (picks) for improved reinforcement

- Over twice the weft strength compared to standard conveyor belts

Key Features:

- Outstanding rip and tear resistance, ensuring longevity in harsh conditions

- Low elongation, providing stable performance and reduced maintenance

- High tensile strength, supporting heavy loads and demanding operations

- Superior adhesion between layers, enhancing overall belt durability

- Excellent impact resistance, minimizing damage from heavy material handling

Cover Grades:

The CFW Rubber Conveyor Belt is available in a range of cover grades to meet various operational requirements. However, due to the extreme conditions in which it is typically utilized, high-performance cover compounds are strongly recommended for optimal wear resistance and extended service life.

This belt is the ideal solution for industries requiring maximum strength, durability, and reliability, ensuring efficient and cost-effective material transportation.

Loading...

Loading...