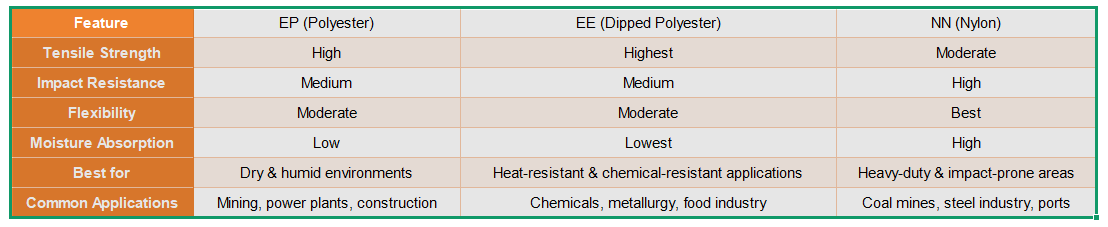

EP (Polyester Conveyor Belt): Best for high-strength, low-elongation applications, suitable for mining, construction, and power plants.

EE (Dipped Polyester Conveyor Belt): Offers dimensional stability and chemical resistance, making it ideal for chemical, metallurgy, and food industries.

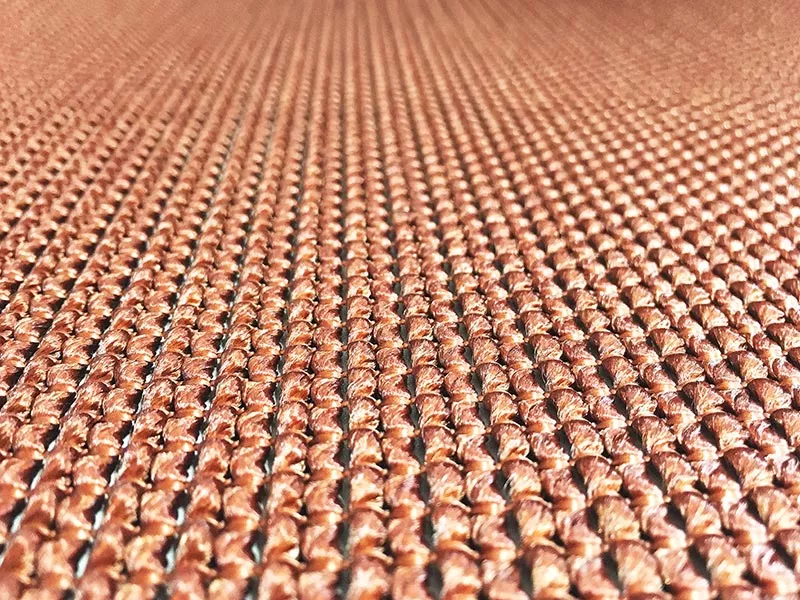

NN (Nylon Conveyor Belt): Highly flexible and impact-resistant, best suited for coal mining, steel plants, and heavy-duty applications.

If you need technical specifications, material recommendations, or customized solutions, feel free to contact us!

Comparison of EP, EE, and NN Conveyor Belts

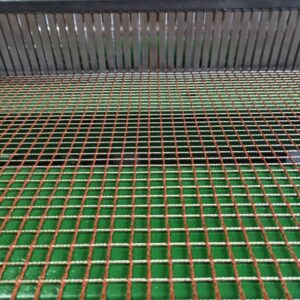

The warp of EP fabric is in form of polyester industrial filament,and the weft is in form of nylon6.6(chinlon6.6)industrial filament and RFL dipping glue.

Product features

High intensity

Good heat resistance

Long servic life

Low elongation

Good troughability

Strong adhesion force

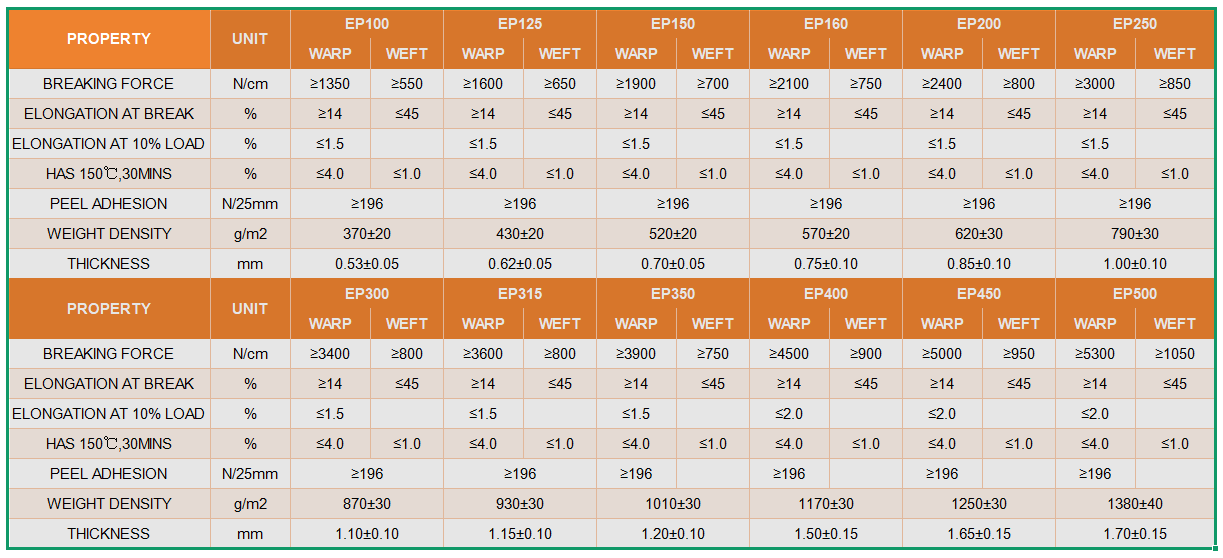

Model

EP-100,EP-125,EP-150,EP-160,EP-200,EP-250,EP-300,EP-315,EP-350,EP-400,EP-450,EP-500

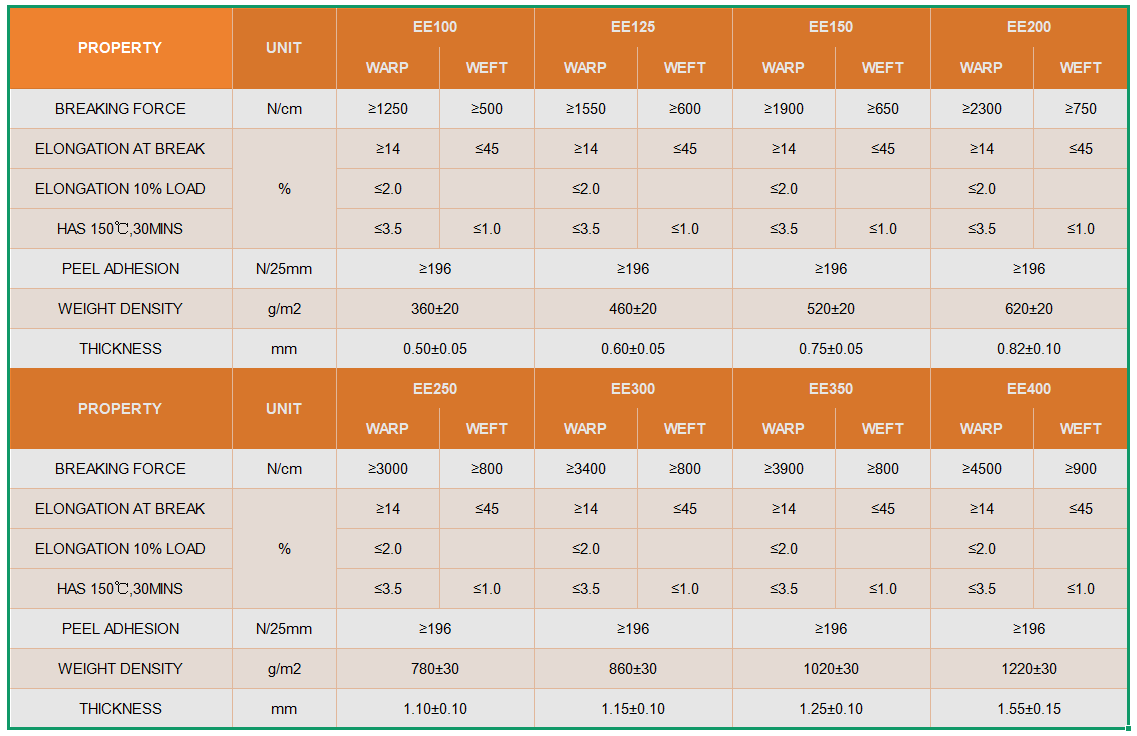

The warp and weft of EE fabric are both in form of polyester industrial filament,with RFL dipping glue.

Product features

Cost advantage

Low elongation of the warp

High intensity

Good shock resistance

Suitable for long distance transportation

Model

EE-100,EE-125,EE-150,EE-200,EE-250,EE-300,EE-350,EE-400

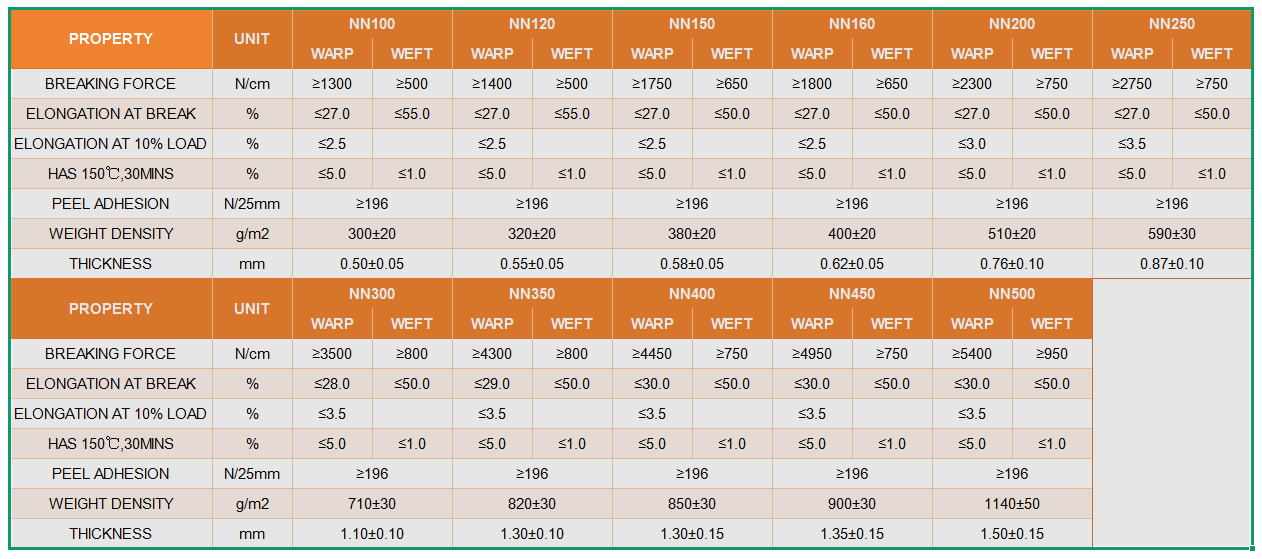

The warp of NN fabric is in form of polyester industrial filament,and the weft is in form of nylon6(chinlon6)industrial filament and RFL dipping glue.

Product features

High intensity

Good bending property and troughability

Good fatigue resistance

Good shock resistanc

Suitable for medium,long distance transportation

Model

NN-100,NN-120,NN-150,NN-160,NN-200,NN-250,NN-300,NN-350,NN-400,NN-450,NN-500