Loading...

Loading...

Loading...

Loading...

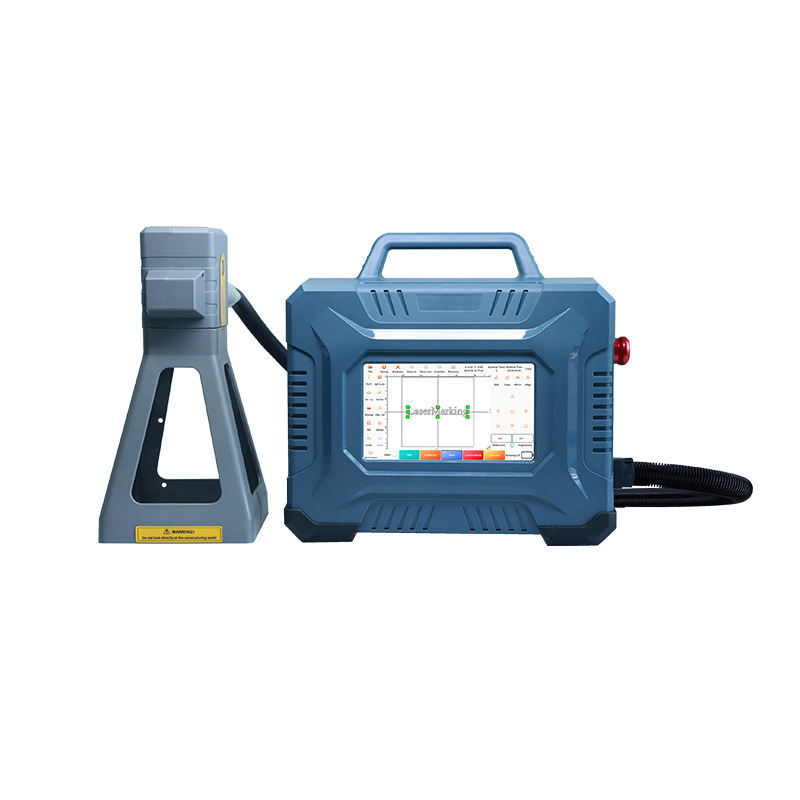

Why Use a Laser Marking Machine?

Using a laser marking machine offers numerous advantages across industries, especially for conveyor belts and industrial components. Here are the key benefits:

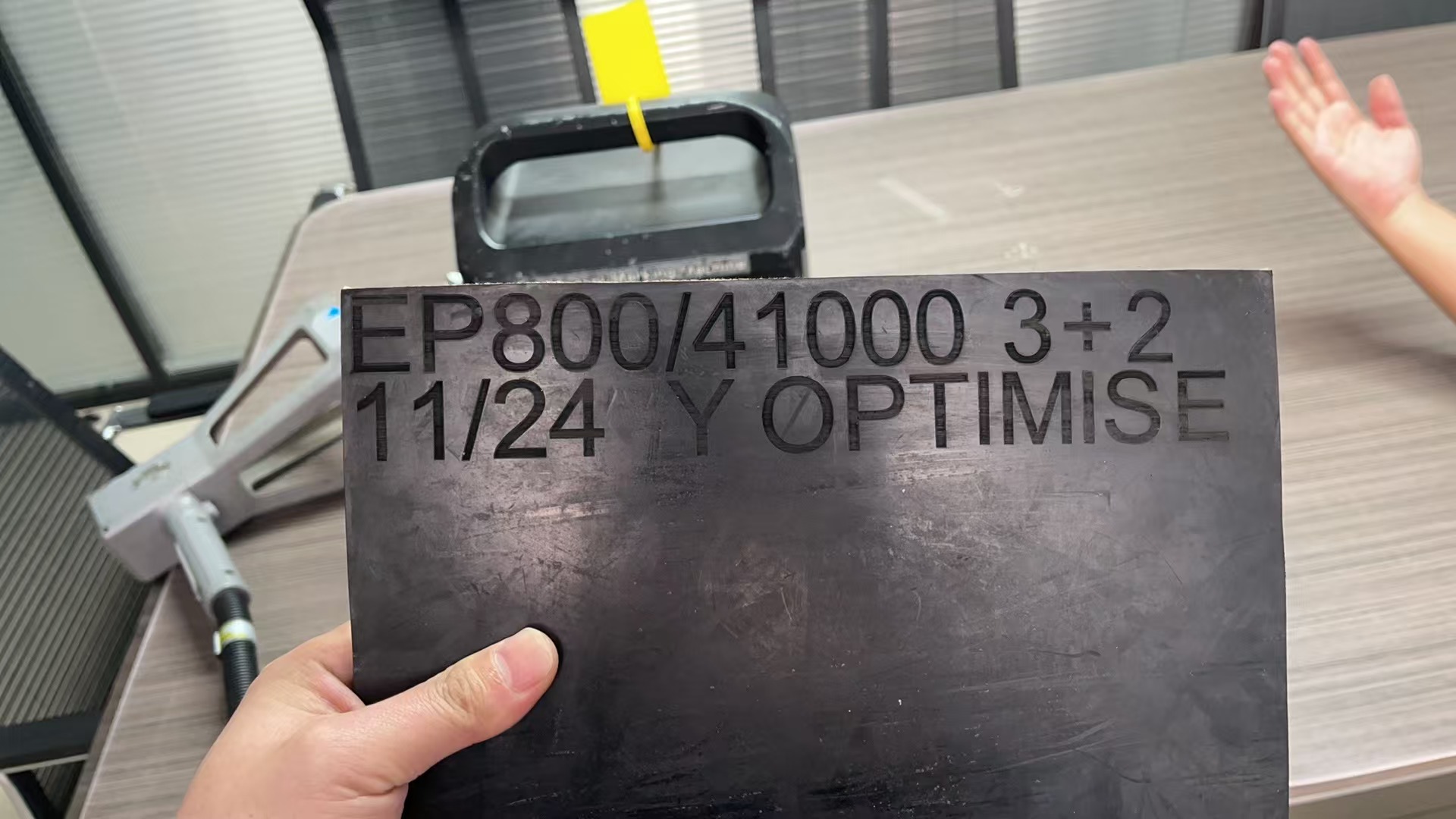

🔹 1. Permanent and Wear-Resistant Marking

Laser marking creates permanent, high-contrast engravings that resist abrasion, chemicals, heat, and moisture.

Unlike ink printing or stickers, laser markings do not fade over time, making them ideal for harsh industrial environments (e.g., mining, steel plants, logistics).

🔹 2. High Precision & Customizable Marking

Crisp and high-resolution text, logos, serial numbers, and QR codes can be engraved with exceptional clarity.

Flexible customization allows variable data marking, including batch numbers, barcodes, and manufacturing dates, enhancing traceability and product identification.

🔹 3. Cost-Effective & Maintenance-Free

No consumables (ink, labels, or printing ribbons), reducing long-term operational costs.

Minimal maintenance required, improving production efficiency.

🔹 4. Compatible with Various Materials

Suitable for marking on rubber, PVC, PU, steel, and plastic conveyor belts.

CO₂ laser works best for rubber & PVC, while fiber laser is ideal for metal surfaces.

🔹 5. Eco-Friendly and Compliant with Safety Standards

No toxic chemicals or waste, making it an environmentally friendly solution.

Compliant with FDA and industry safety regulations for food-grade conveyor belts and medical applications.

🔹 6. High-Speed and Non-Contact Processing

Non-contact marking process prevents material damage.

Enables real-time, inline marking on production lines, increasing efficiency.