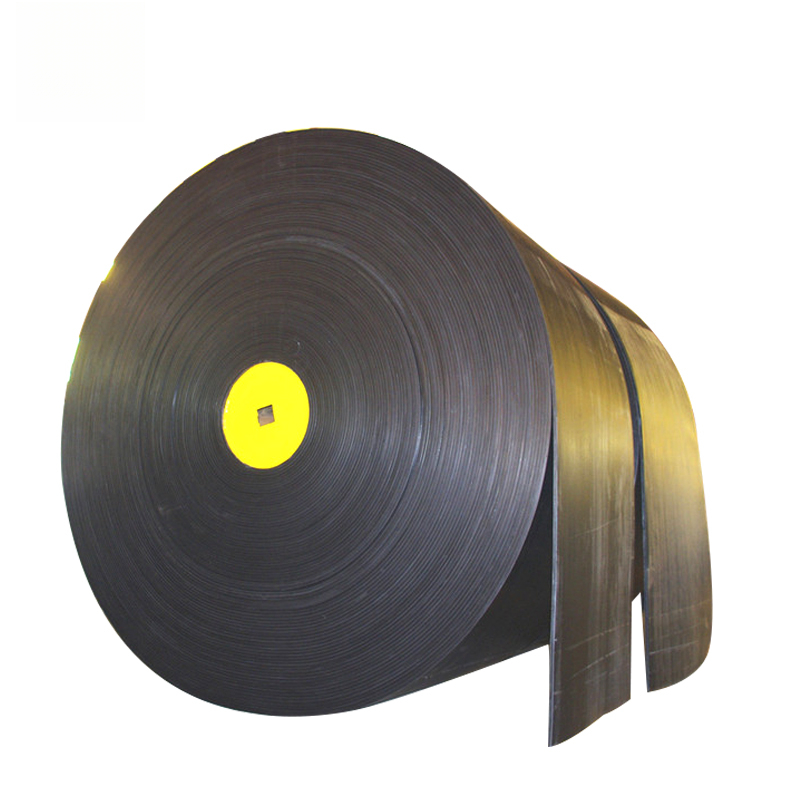

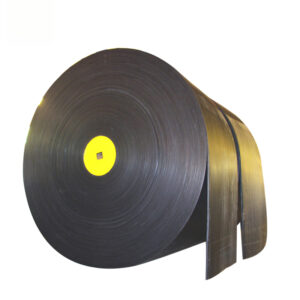

Product Structure

The flat transmission belt is engineered with premium cotton canvas as its core skeleton layer, utilizing an innovative multi-layer lamination process. Precision vulcanization technology ensures permanent adhesion between rubber layers and reinforcement materials. A proprietary curved-edge joint design eliminates stress concentration at traditional seams.

Key Advantages

- Superior Power Transmission: 30% increased tensile strength, industry-leading elastic modulus, and operational elongation rate <0.5%, ensuring zero power loss.

- Breakthrough Bonding Technology: Patented rubber compound formula enhances interlayer adhesion by 80%, resolving delamination failures common in conventional belts.

- Military-Grade Durability: Long-staple cotton canvas layers withstand 2 million ISO 4183-compliant flexing cycles while retaining 98% original integrity, with 2.5x improved deformation resistance.

Application Scenarios

◆ Heavy Industry: Power transmission for metallurgical rolling mills, continuous mining crusher operations, and core drive systems for port handling equipment.

◆ Modern Agriculture: Large-scale grain processing units (wheat, rice), smart irrigation systems, and forestry machinery power transmission.

◆ Precision Manufacturing: CNC woodworking machinery, automated assembly lines, and food-grade processing equipment.

Classification

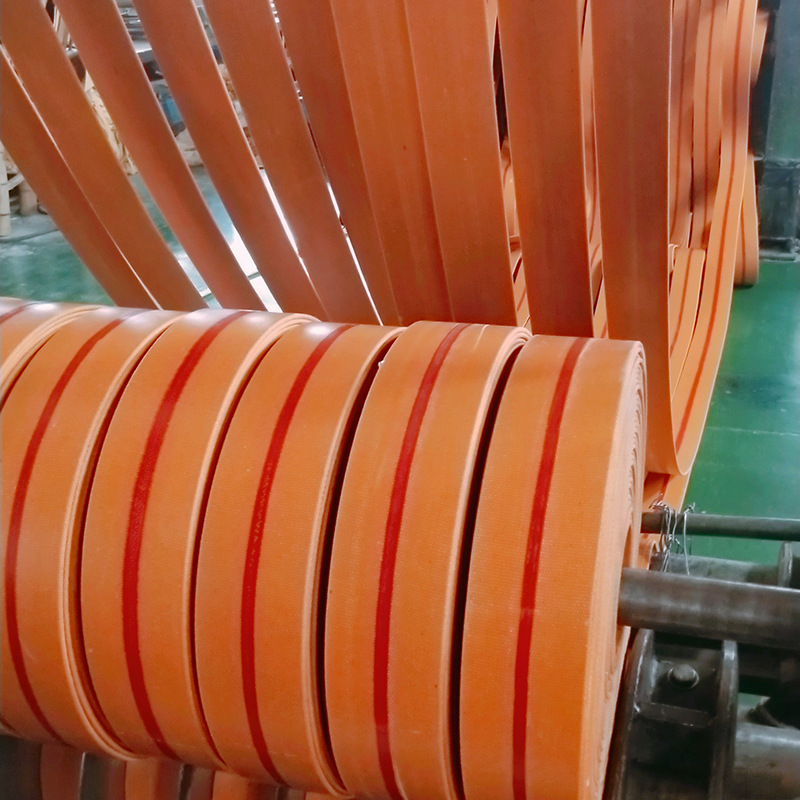

1. Category: 28 OZ(ounce), 30 OZ(ounce), 32 OZ(ounce), 34 OZ(ounce) and 36 OZ(ounce).

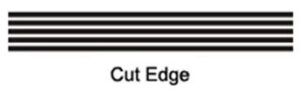

2. Cut edge flat rubber belt: Cut edge flat rubber belt is manufactured by adhering several layers of full width

canvas together, the sides of the belt are surfaces formed by cutting, the belt edge surfaces are coated

with rubber paste.

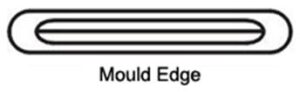

3. Round / Mould edge flat rubber belt: Round edge flat rubber belt is folded by the outer ply or plies of can-

vas, and the sides of the belts are curved surfaces.

4. Available in variety of colors, mainly of them have four colors: light brown, yellow, orange and black.